Bioreactor ondersteunt waterkwaliteit en plantvitaliteit op Pepper Farm

‘Lower Aphid Pressure Thanks to Strong Roots and Tougher Plants’

Since pepper grower Arthur Mooijman began focusing on plant resilience, his plants have remained healthier and suffered less from diseases and pests. The effects have become even more pronounced since he started using a bioreactor that aerates and microbiologically enriches the irrigation water. “Plants benefit more from oxygen-rich water with beneficial microorganisms than from sterile water,” he says with conviction. “I no longer have root diseases, and my plants are clearly more vital and stronger.”

The purchase of an Agrona bioreactor in 2022 marked a new step in Mooijman’s journey toward resilient cultivation, which he had already begun several years earlier. “It actually happened by chance,” recalls the Nootdorp-based grower. “At the time, I was also growing cucumbers. It was a year with poor prices, and just then, my UV disinfection system broke down. There wasn’t enough money to replace it right away, so I was anxious about how the water quality would hold up. Strangely enough, my crops seemed to respond positively to the fact that the return water was no longer being disinfected and microorganisms weren’t being killed. That got me thinking.”

Resilient Cultivation

Mooijman delved deeper into resilient cultivation and adopted Koppert’s Natugro concept. “The plants responded well to it,” he says. “I saw a more vigorous and stronger crop, which was less susceptible to diseases and pests. We also adjusted the fertilization strategy, mainly reducing nitrogen application. This also contributes to a tougher crop, making it less attractive to pests like aphids.”

Bioreactor

A few years later—by then, the financial situation had improved—the grower purchased a second location in Berkel en Rodenrijs, where he started growing peppers, fully transitioning to pepper cultivation. “There was also a UV system that needed replacing, but water disinfection no longer fit with my cultivation methods,” Mooijman adds. “Instead, in February last year, we installed a bioreactor, about which I had already heard and read quite a bit.”

How It Works

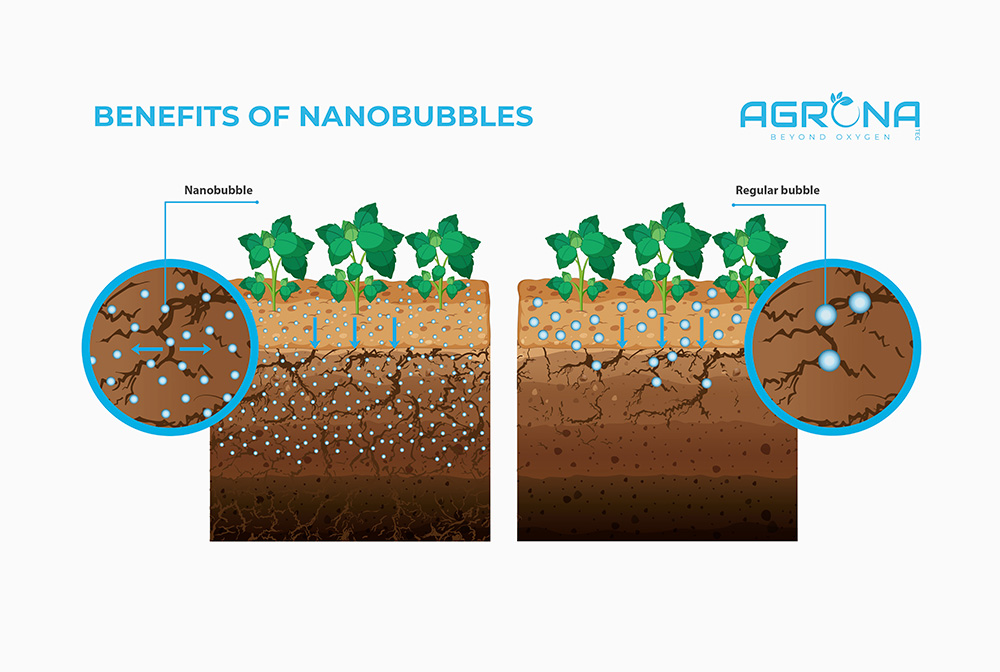

The bioreactor operates by aerating, microbiologically enriching, and purifying the irrigation water. The reactor tank contains a growth medium where beneficial microorganisms can settle and multiply. The grower must add specific cultures of fungi and bacteria, including species like Trichoderma and Bacillus. The AG Stim nutrient solution, also supplied by the bioreactor manufacturer, promotes the growth and multiplication of the microorganisms.

The water in the reactor tank is aerated to create an oxygen-rich water environment. “That’s good for the beneficial microorganisms and not so good for pathogens,” the grower explains. “An added benefit of oxygen-rich water with good microorganisms is that it breaks down and transforms pathogens and organic pollution, keeping pipes and drippers clean. In the mats – we only use organic mats now – the beneficial bacteria and fungi can settle structurally.”

Positive Effects

Mooijman suspects that the positive effects of the bioreactor work even better in organic mats. “They offer a better environment for microorganisms than rock wool mats,” he observes. “I see that the crop at the new location looks even more vital and stronger than here in Nootdorp. At both locations, analyses show that the pressure from pathogenic fungi like Pythium is very low. In Berkel and Rodenrijs, aphid pressure is remarkably low, and the plants appear even stronger and more vital. It’s always difficult to compare different locations and greenhouses, but I’m confident that the production and fruit quality at the location with the bioreactor are at least on par with last year, and maybe even a bit better. The focus on resilience is definitely paying off.”

Text: Jan van Staalduinen, Image: Marleen Arkesteijn